Continental E-series engines are all 470 cubic inch displacement. 185, 196 , 205, and 225 hp are all determined by max engine RPM. Each of these HP combinations have some slight crankshaft balancing features allowing these RPM differences. Consequently, not every E-Series crankshaft can be used interchangeably.

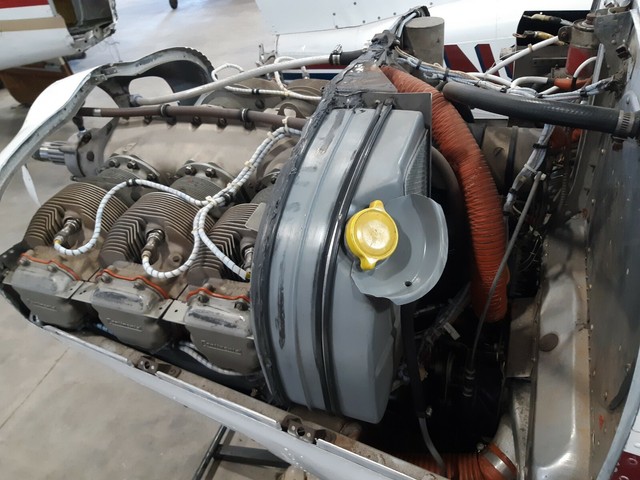

What makes the E-Series engine unique is they are dry sump engines. That means, the oil tank is separate from the engine. A wet sump engine has a sump…an oil pan… attached to the bottom of the engine to contain the engine oil. Many race cars, high performance engines in off-shore competition boats, and motorcycles have dry sump engines. The separate oil tank also has a built in cooling radiator that requires careful attention paid to the amount of oil in the oil tank. Too much oil can cause high oil temps as well as too little oil.

In wet sump engines, when you shut down the engine, the oil drains downward into the oil sump…oil pan…located on the bottom of the engine on most air cooled aircraft engines. Normal procedure is to check the oil cold during the pre-flight inspection because all the oil has drained down into the oil sump.

On an E-Series dry sump engine, one checks the oil level immediately after shutdown. Should you decide to check it in the morning, 2-4 qts have slowly drained into the engine crankcase. In most cases, there will be no oil on the dipstick at all. The natural inclination is to add enough oil to get the level to read on the dipstick. This leads to over filling the oil tank, potentially causing it to rupture. At the very least, this excess oil will be dumped overboard via the engine breather system completely saturating the belly of the airplane. And in many cases, filling the belly skins up with oil, adding further to what appears copious amounts of oil making your airplane a leaking, oily flying sieve. This over filling of the oil tank can also lead to oil leaks around the magnetos, vacuum pump, and generator/alternator, and accessory case at the rear of the engine where all these parts are located. There is a scavenge pump that empties the engine of all the drain back oil in about 30 seconds re-filling the oil tank. So, if you forgot to check the oil immediately after shut down, you would have to start the engine cold running it for a minute or two, and then shut it down to accurately check the oil.

While E-Series engines have a 10 quart capacity, if you fly with that much oil, the first quart will be quickly sent overboard via the air/oil separator (another oily belly experience). However, while you burn enough oil to get down to the ideal “sweet spot” for optimum oil temps, it is not unusual to experience high oil temps. Depending on what an E series Continental engine’s average oil consumption really is, makes long cross country flight planning a little more detailed to ensure enough oil available but not over-filling to maintain good oil temps through out the flight, especially in high summertime afternoon temperatures. E-series Continentals generally suffer from low oil pressure when in comparison to later big bore six cylinders. Cruise minimum oil pressure is 30 PSI. Minimum idle pressure is 10 PSI. High oil temps lower oil pressure. Quite easy to get to these minimums if your engine is operating with high oil temps.

As a result, a prudent first generation Bonanza pilot checks the oil immediately after shut down, makes sure to keep oil capacity at 8 quarts, and flight plans with knowledge of accurate oil consumption to keep the oil in the oil tank as close to 8 quarts as possible for long cross countries.